See related blog (http://wormmainea.blogspot.com/2010/08/home-efficiency-2010-continued-flir.html) for initial FLIR photos and discussion. Since the original audit we undertook a number of retrofits as discussed in related blogs

http://wormmainea.blogspot.com/2010/08/home-efficiency-2010-continued.html, http://wormmainea.blogspot.com/2010/09/air-sealing-top-and-bottom-of-house.html, http://wormmainea.blogspot.com/2010/10/water-heater-wrap-up.html,

http://wormmainea.blogspot.com/2010/11/air-sealing-electrical-outlets-on.html, and http://wormmainea.blogspot.com/2010/11/work-in-attic-air-sealing-and.html

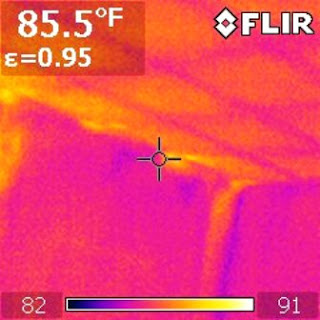

The following show side-by-side photos before and after for same or similar areas of our home. Note that the temperature difference between inside and outside is greater now than when the audit was conducted back in August (44° vs. 65°) as compared to (82° vs. 95°). A greater difference inside vs. outside would mean that any air movement would show up more easily in the FLIR camera.

|

| Before photo of the porch |

|

| After photo of the porch. |

|

| Before photo of the attic hatch. |

|

| After photo of the attic hatch. |

|

| Bert's office before. |

|

| Bert's office after |

|

| Basement sill before |

|

| Basement sill after |

* Erik said: "The final value for my home was 1585 CFM and the final savings [as calculated by the software] was 36%. I've mentioned a few times that EM's software is pretty generous but I'd be comfortable saying real world savings around 25% [that's the number I'm using]. Another question that may arise is whether the house is 'too tight' and that it 'needs to breathe'. The BTL (Building Tightness Limit; the engineered standard for necessary air flow) for your house was 1343 CFM50. That's the point at which you need to begin adding mechanical ventilation to make up for natural air flow. You can compensate with intermittent ventilation to 70% of BTL (940) after which dedicated continual ventilation is needed. So your house is well over the various air thresholds."

I can't wait to save money and be more comfortable this winter.

Cheers,

Mark